PTB 500 Automated Tablet Testing

PTB 500 Semi-Automated Tablet Testing System with Integrated Balance

The semi-automated tablet testing system PTB 500 is a dual test mode instrument to measure five different parameters of one sample - Hardness, diameter (or length), thickness, width and the weight of tablets can be measured automatically The instrument features an integrated analytical balance or a connection for an external balance and a sample carousel. The instrument is made in strict compliance with the EP <2.9.8> and USP <1217> Pharmacopoeia.

PTB 500 features a carousel to transport the samples between the weight, thickness and combined width, diameter (or length) and the hardness testing station. The measuring units can be selected from mm or Inch and KP (Kilopond), N (Newton) or Sc (Strong Cobb).

PTB 500 features a large, back-lit colour LCD. Navigate the menu using the touch screen or connect a standard keyboard and mouse. There are two ways to start a test with PTB 500 – start a quick test immediately after powering on the instrument without logging on or login to start a method-based test.

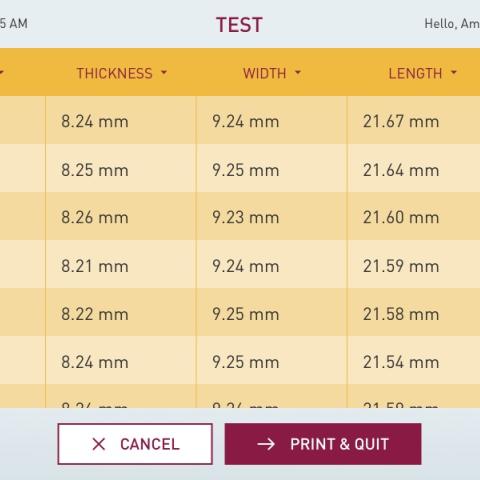

The samples are automatically transported to the test stations by the rotating carousel. First the weight is measured by the integrated Sartorius analytical balance. Then the thickness is measured and third comes the combined diameter (or length) and hardness testing station. It is also possible measure the width of the sample. In this case the operator is prompted to position the sample accordingly in the test station. Now for the diameter (or length) and hardness measurement the force jaw will move forward, touch the tablet at its highest point to measure the diameter and immediately its hardness (tablet breaking force). Finally, the broken sample is discarded into the waste container.

Results

When printing via either a printer directly connected by USB or a network printer three options are available: print the data including each individual result as well as product information, date, time, user, instrument serial number, statistics can be added to this information of just print the breaking curve of the last broken tablet. It is always possible to activate or de-activate separate testing stations. This way it is possible to just test the hardness of a tablet without measuring any other parameters. For this, deactivate the other parameters like thickness by leaving the field for the nominal value and number of samples empty.

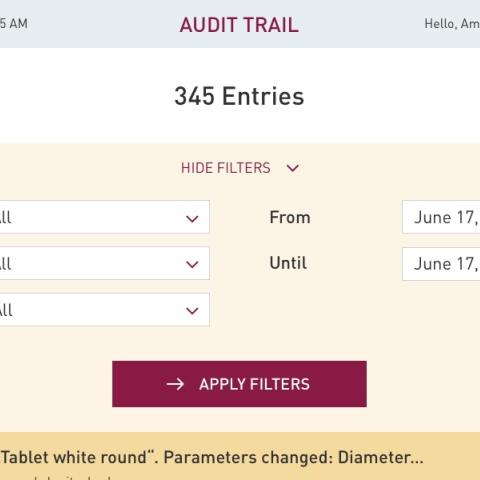

Audit Trail

PTB 500 features and audit trail that records all events according to 21 CFR Part 11 requirements. The events can be displayed on the instrument itself and be printed for examples as PDF for documentation purposes. The events of the audit trail can be filtered by user, product, method and date of the event. For each event a detailed description is available with mention of the related user, method and product and which value has been changed from what to what.

Additional Images