Capsule Polisher

CAPSULE HANDLING AT A HIGH LEVEL - KCP10

The Krämer capsule polisher will elevate, polish and dedust any size of capsule. The rotational spiral brush designed specifically for capsule applications polishes gently and removes excess dust. The perforated housing allows ideal aspiration of the dust. The device outlet can be fitted with peripherals such as metal detectors, empty capsule sorters, diverter switches and slides.

- Upward conveying range of 800 to 2000 mm

- Dust-tight Tri-Clamp connections

- Quiet operation < 68 dB

- Speed continuously adjustable

- Optimal cleaning of capsules with gentle conveying

- Compact design, minimum footprint

- Modular structure (400 mm)

- Easy assembly and disassembly, no tools are needed

- Easy to clean

- Classification: Atex Zone II 2D/- Db 140 °C

Conveying Capacity up to 300'000 capsules per hour

EASY TO USE CONTROL PANEL

The KCP10 and KCP15 utilize a simple frequency controller that allows for continuously adjusting the conveying speed. In addition, the power supply cable uses a quick connect plug. The quick connect plug allows for use of preassembled cables with power supply as well as signal wire options for communication to upstream equipment such as capsule fillers.

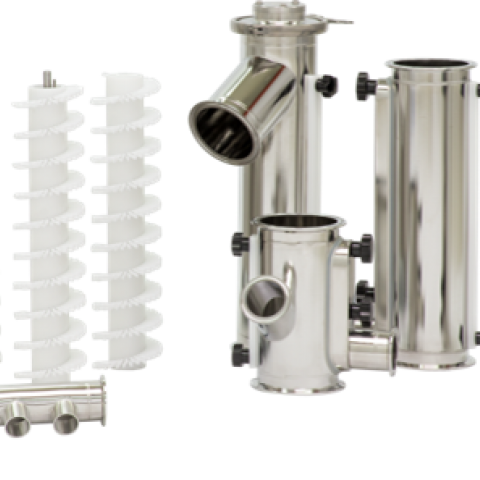

BRUSH DESIGN – AN INNOVATIVE APPROACH

The rotational spiral brush designed specifically for capsule applications polishes gently and removes excess dust. With our unique stepless design between brush modules, we do minimize product jam and guarantee continuous product conveying. Every single brush module can be marked accordingly in order to keep track of dedicated products.

CONNECTION PORTS

With the use of optional inlet adapters, the capsule polisher is easily adjustable to various capsule filler discharge configurations. If an adapter is not being used, a hose can directly be attached to the Tri-Clamp inlet. The inlet can be rotated 360° independent of the outlet. All Krämer capsule polisher feature a 2 inch Tri-Clamp vacuum dust collection port for ease of assembly of a dust collection hose. Various optional hose adaptors are available upon request. The perforated housing allows ideal aspiration of the dust on each module independently.

EASE OF ASSEMBLY AND DISASSEMBLY

No tools are needed to assemble or disassemble the machine for cleaning. All product contact surfaces are AISI 316L stainless steel. All Krämer machines minimize the number of parts to be cleaned, and keep the weight of each part minimal for ease of handling. This assures quick and effortless cleaning processes.

Additional Images