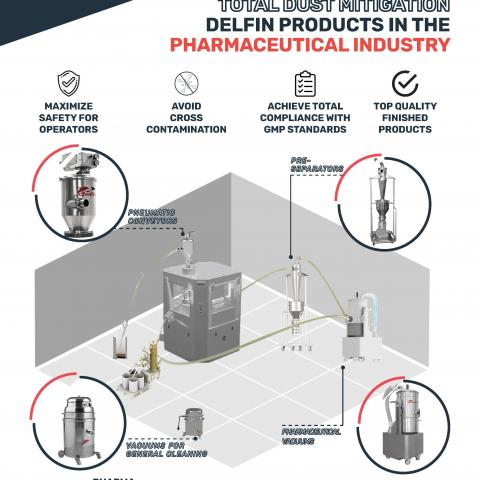

Complete Dust Containment Solutions

Containment Solutions for Pharmaceutical and Nutraceutical Powders

VACUUM SOLUTIONS FOR ELIMINATING CONTAMINATION RISKS

There are 3 types of cross-contamination:

✓ Physical contamination; fragments and dust from compression machinery

✓ Chemical contamination; steam, humidity, molecules

✓ Biological contamination; bacteria, fungi, viruses

GMP calls for the use of appropriate equipment and measures to prevent products from being contaminated by external agents. This equipment includes industrial vacuum cleaners with HEPA filtration. Installed on production lines or in departments, these are the most efficient, fastest, and safest solution.

Using industrial vacuum cleaners to clean the workplace gives you the ability to:

✓ Maintain the highest level of hygiene in the work environment (floors, machinery, tools), by preventing the re-circulation of contaminated materials.

✓ Remove dust at source, at strategic points in the production process

✓ Eliminate any possibility of foreign body contamination in the production process

Stainless steel construction, multiple levels of HEPA dust filtration, smooth surfaces and easy sanitation are the key characteristics of industrial vacuum cleaners designed for the pharmaceutical industry

GENERAL CLEANING and DUST EXTRACTION

Three-phase industrial vacuum cleaner are ideal for large filtration areas and surfaces designed to prevent the accumulation of dust. These units are perfect for connection to:

- Tablet press and Encapsulation machines

- Production filling machines

- Packaging Equipment

VACUUM CLEANERS FOR CLEAN ROOMS

Each piece of equipment used in the cleanroom must comply with the relevant ISO classification. Specifically designed to be easier to sanitize and maintain, Delfin has engineered a specific range of industrial vacuum cleaners known as the LabControl range. These units are idea for:

- Tablet Press and Capsule Machine clean-up

- Wet or Dry application

- Packaging Lines

- Laboratory Use

Additional Images

PNEUMATIC CONVEYORS FOR PHARMACEUTICAL POWDERS

Transporting powders, granules, and solids within the production process is a delicate phase and has the potential to lower the quality of the finished product. Contamination is the most significant risk, and a closed transport system can minimize the risk. Pneumatic conveyors are an excellent option to ensure efficiency and protect product quality. These units are ideal for:

- Tablet Presses and Capsule Machines

- Blenders and IPC

- Hopper Filling for Packaging Equipment