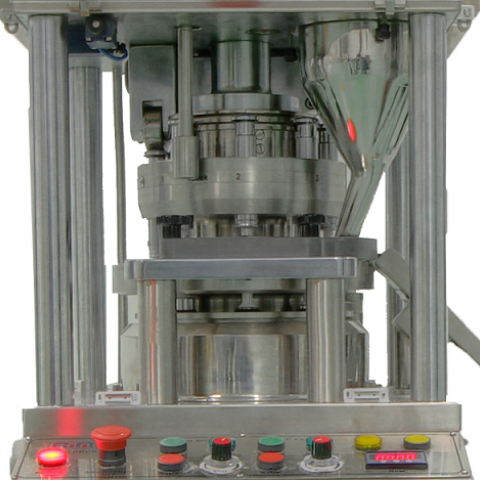

Mini Press II

Cost Effective Rotary Tablet Press with Pre-Compression

The Mini Press II is an ideal tablet press for free flowing powders used in formulation development labs, universities, and small batch production where Pre-Compression is needed. Also available is an optional Force-Feeder. This small and sturdy single sided rotary tablet press is designed as per cGMP considerations. The machine runs at low noise level. The speed is controlled via an ACVF drive and is easy to operate, maintain and clean. The Mini Press II also comes in a Bi-Layer option.

Ideally suited for:

- Product development and formulation labs

- Laboratory, Hospitals, Dispensaries, Academics use

- Small Volume Production

- Pharmaceutical, Nutraceutical, Confectionary, Cannabis

- High value low volume products

Machine design:

- Machine is compliance with cGMP norms for design, Control System & cleaning

- Machine is held on Stainless Steel Trolley (optional) for mobility

- Upper acrylic guard interlocks

- Table top model for easy mobility

- Machine base is totally enclosed with openable covers for access to motors & drives inside.

|

Model |

Mini Press II

|

Mini Press II -10 |

Mini Press II -MT |

|

No. of stations |

8 |

10 |

(6+6 ) |

|

Tooling |

D |

B |

D+B |

|

Tablet diameter (Max.) in mm |

23 |

15 |

23/15 |

|

Depth of fill (Max.) |

20 |

17 |

20 |

|

Tablets/hr (Max)* |

15360 |

19200 |

7680 |

|

Turret RPM (max) |

32 |

32 |

32 |

|

Max. compression in tons |

6 |

6 |

6 |

|

Max. pre-compression in tons |

2 |

2 |

2 |

|

Electric motor |

2 HP, 1440 RPM, 415V AC, 3 PHASE |

||

|

Force Feeder motor |

0.125 HP,220V AC, 75 RPM, 50HZ, Single PHASE |

||

|

Machine size in mm |

670×460 × 1100 |

||

|

Net weight in kg. |

395 |